Application Scenarios

Make combustion cleaner, more efficient and safer

DURAG Fire Detection Renovation Case

Background of the project

◆ Boiler information: 2X315 MW four-corner tangential boiler

◆ Manufacturer: Dongfang Boiler Co., Ltd.

◆ Number of coal burners: 24

◆ Number of oil burners: 12

There is a problem

◆ The detection capability of the original flame detector is weak, the fire detection signal fluctuates greatly, the anti-interference ability is poor, and the failure rate is high;

◆ The original equipment product has poor adjustability and adaptability, and cannot adapt to complex combustion conditions;

◆ The original flame detector The temperature resistance is low, the ambient temperature of the boiler site is high, and the fire detection probe is seriously damaged by overheating;

◆ Split structure, the overall spare parts are expensive, and the delivery time is long;

Solution

◆ Replace the original DURAG D-LE 703 fire detector with Safe-Fire’s W-FLAME series fire detector, which has stable performance and strong anti-interference ability;

◆ By adjusting parameters such as bandwidth, frequency, gain, etc., W-FLAME fire detector It can accurately reflect the burning condition of the target flame;

◆ The new fire detection probe has a temperature resistance of 85°C, a 40% increase in temperature resistance, and can adapt to high temperature and high dust working conditions;

◆ Safe-Fire's W-FLAME series integrated fire detection Specialized design, short delivery cycle and high cost performance.

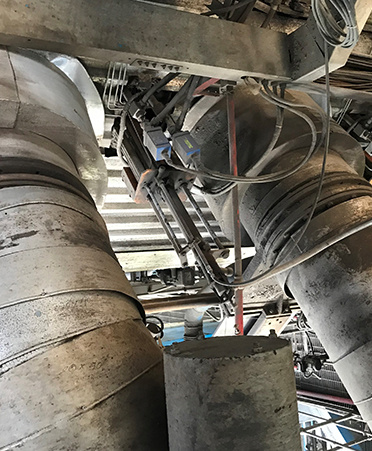

On-site installation photos

Transformation of the former

After transformation

Specifications

|

product name |

D-UG 120/D-LE 703 IG-P |

W-FLAME |

|

brand name |

DURAG |

SAFE-FIRE |

|

Spectral response range |

780-1800nm |

900-1700nm |

|

signal processing technology |

MCU processor |

DSP high speed microprocessor |

|

Operating environment temperature |

-20℃-+60℃ |

-40℃-+85℃ |

|

Protection level |

IP66 |

IP66 |

|

Debugging mode |

Use potentiometer for parameter setting |

Panel debugging, network debugging |

|

Detection performance |

Detect AC (flicker amplitude) and frequency signals, no bandwidth settings, frequent debugging is required after coal quality changes |

AC (flicker amplitude) and frequency signals, with bandwidth settings to prevent mixed detection of kerosene, prevent low-load peeking, strong adaptability |

|

output signal |

"Fire" switch value, fault alarm, flame intensity: 4-20mA |

"Fire" switch value, fault alarm, flame intensity: 4-20mA |

Result

◆ The flame detector operates stably, which improves the safety of the fire detection system;

◆ The protection of the fire detection system can be put into normal operation, improving the safety of the boiler;

◆ The fire detection detector adopts an integrated design, which eliminates the need for debugging and reduces the maintenance workload. Improved user experience.