Application Scenarios

Make combustion cleaner, more efficient and safer

Fire inspection upgrade case analysis: Oriental Hualong Haixing hydrogenated heat conduction oil furnace fire inspection replacement application

As the "eyes" of the boiler, the fire inspection system plays a vital role in the whole process from boiler start-up to safe operation.

Project Background

Shandong Oriental Hualong Industry and Trade Group Co., Ltd.'s heat conduction oil furnace (F3101) was originally equipped with the DURAG D-LX 201 UA fire detection probe due to its short service life, damaged after a period of use, and the output of the detection flame signal is also unstable, resulting in frequent maintenance, bringing hidden dangers to the normal operation of the equipment, and reducing the operation efficiency to a certain extent. In addition, after-sales service cannot be guaranteed, so it is urgent and necessary to optimize and upgrade the boiler fire inspection system.

solution

In view of the importance of the fire detection system, Safefire has adopted an optimized upgrade method by selecting the W-Flame 21 CEX ultraviolet explosion-proof fire detection for upgrading.

Upgrades & Effects

Replacement of the original DURAG D-LX 201 flame detector with the Safefire W-Flame 21 CEX fire detection probe;

The W-Flame 21 CEX fire detection probe can withstand temperatures up to 75°C, and the ambient operating temperature is higher and more durable.

The W-Flame 21 CEX fire inspection can be adjusted by real-time flame signals on site, so as to more accurately reflect the combustion of the flame.

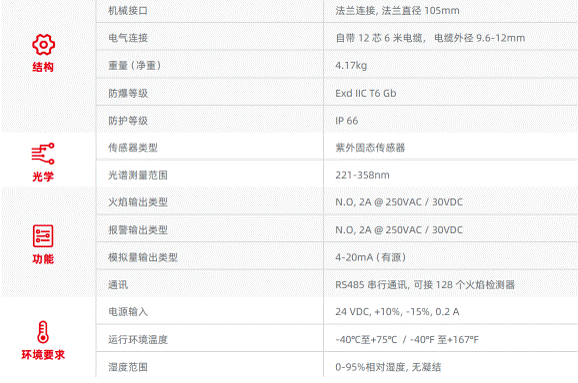

Specifications

Case summary

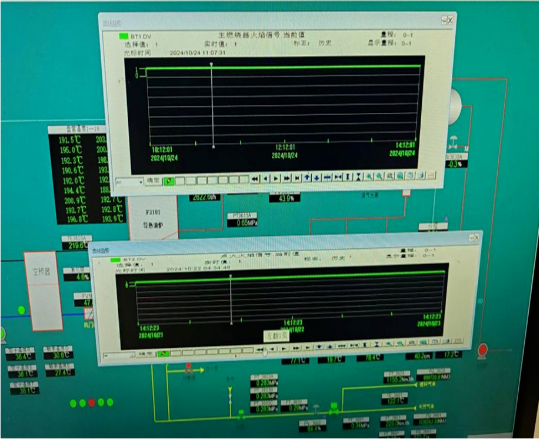

In this renovation project, after replacing the Safefire W-Flame 21 CEX flame detector, the on-site fire detection signal output is stable and reliable (see the trend chart below), which greatly improves the safety and stability of the operation of the heat transfer oil furnace.

At the same time, after the on-site system is powered on and debugged, the integrity and reliability of the fire inspection system are ensured, the frequency of fire inspection maintenance/replacement is reduced, and the maintenance workload and replacement cost are reduced.

The fire inspection is debugged according to the real-time flame, so that the fire detection system can correctly reflect the combustion conditions, which is more safe and reliable. In the end, the production and operation of Shandong Oriental Hualong Industry and Trade Group Co., Ltd. was guaranteed on schedule, and won the praise of customers.