Application Scenarios

Make combustion cleaner, more efficient and safer

The TempVision 5000 project of the Ratu power plant in Indonesia was put into operation, achieving transparent combustion

Realize from blind burning to transparent combustion, and create favorable conditions for combustion adjustment. In 2019, the Ratu Power Plant in Indonesia partnered with Safefire to purchase a TempVision 1000 portable unit to solve the problem of combustion visualization to cope with more complex combustion profiles. Through combustion adjustment, the power plant also achieved real-time boiler combustion efficiency improvement and energy-saving results.

In 2021, it won the Indonesian National Energy Conservation Award. In 2024, Ratu Power Plant and Safefire have joined forces again to purchase the TempVision 5000 on-line system.

Project Background BACKGROUND

Ratu Power Plant, Indonesia

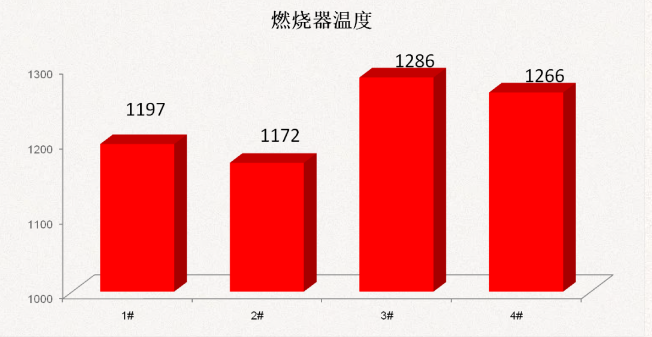

Boiler 3*300MW, four corners cut circle combustion

Manufacturer Shanghai Boiler Factory

24 burners

Project information INFORMATION

TempVision 5000 is an on-line real-time temperature monitoring system

It can be used to monitor the flame temperature field inside the boiler burner and furnace in real time, and the system can be adapted to a wide range of boiler types thanks to a combination of temperature field probes and process communication suites.

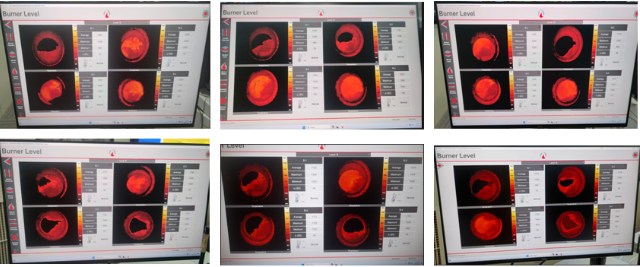

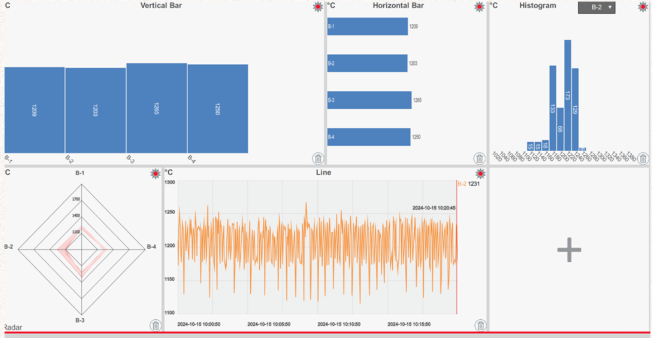

The system provides operators with accurate combustion temperature data, and grasps the temperature distribution, change curve and trend, flame dynamic characteristics of the boiler burner flame in real time through the visual monitoring of the combustion area inside the furnace.

A large number of temperature data analysis has a guiding role in the leveling of primary air powder in hot and cold states, the adjustment of secondary air volume and wind speed, the swing angle of the burner, and the adjustment of oxygen content at the outlet of the boiler. Through combustion adjustment, the combustion efficiency of the boiler can be improved, coal consumption can be reduced, and the problems of coking and pollutant formation caused by partial burning and over-temperature can be improved.

The TempVision 5000 system provides big data analysis for the refined adjustment of boiler operation in power plants, and will become an important part of the future thermal power smart power plants.

Features:

• Real-time online monitoring

• Measurement error of less than 1%

• Measured values are not affected by flue gas flow and emissivity fluctuations at high temperatures

• Complete communication interface for process control system

• Modular design for easy maintenance and configuration

Case summary

After the project was put into operation, it not only realized the upgrading and transformation requirements of the boiler of Ratu Power Plant from blind burning to transparent combustion, but also provided 24-hour online data support for subsequent combustion adjustment.

In the future, Safefire will also take this cooperation as an opportunity to continue to deepen cooperation with Ratu Power Plant in Indonesia, continue to focus on the field of boiler combustion, and help safe production and achieve energy conservation and emission reduction.