Application Scenarios

Make combustion cleaner, more efficient and safer

PTMS test case of Song Hau power plant in Vietnam

Background / Introduction

On November 27, 2024, Safefire was invited by the Song Hau Power Plant in Vietnam to conduct a temperature check on the combustion of its unit #1 boiler.

The purpose of this service is to optimize the combustion process and promote the improvement of combustion efficiency through accurate measurement and in-depth analysis of the flame temperature distribution of the burner in the boiler.

Test Object

Crew Number: #1

Boiler capacity: 600MW

Test burner :

A1 to A5; B1 to B5; C1 to C5; A total of 20 burners from E1 to E5.

Test equipment and methods / Project progress report

The test equipment used in this service is the Tempvision1100 portable bichrocolor spectral temperature measurement device developed and produced by Safefire for the measurement of the flame temperature field of boiler burners.

The equipment uses two-color spectroscopy to measure temperature, which has the characteristics of high precision and strong anti-fly ash ability, and at the same time, because of its unique optical acquisition structure, the equipment can collect flame temperature signals through the on-site fire detection catheter, which is easy to operate.

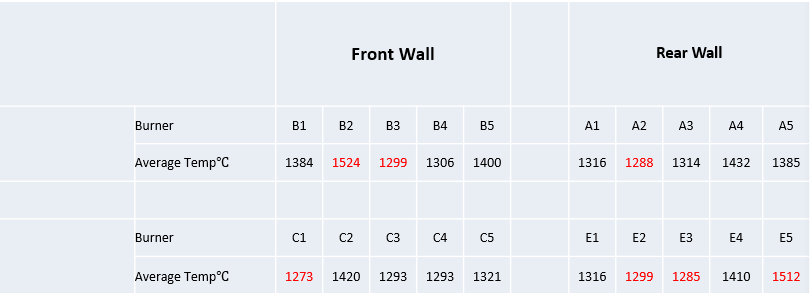

Temperature data collection results

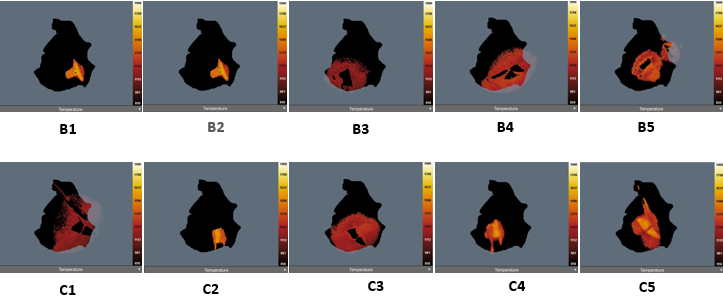

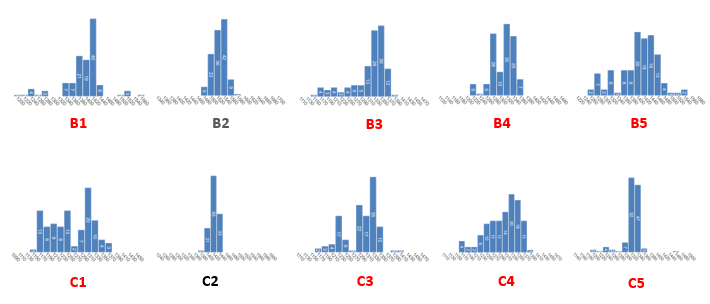

Front wall burner image

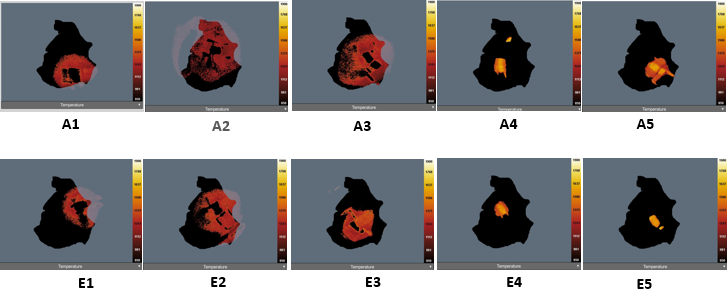

Image of a rear wall burner

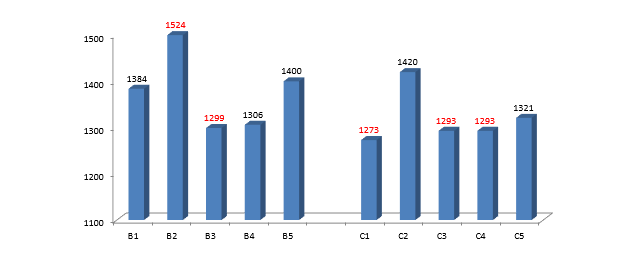

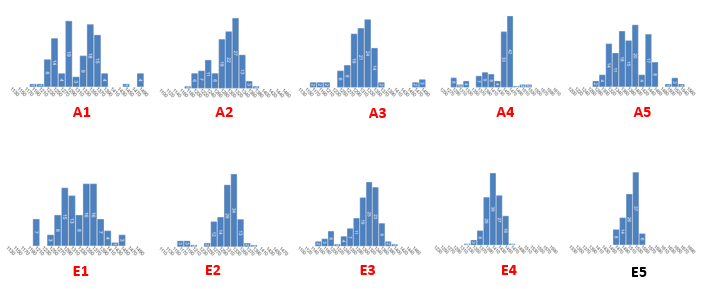

Analysis of the average temperature data of the front wall

B Maximum temperature - 1524°C (B2)

B Minimum temperature - 1299°C (C1)

B Average temperature - 1382°C

B Burner temperature deviation - 225°C

C Maximum temperature - 1420°C (B2)

C Minimum temperature - 1273°C (C1)

C Average temperature - 1320°C

C Burner temperature deviation - 147°C

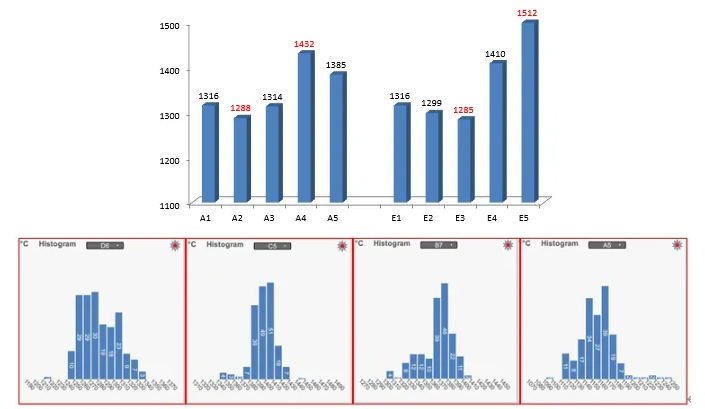

Analysis of average temperature data of the back wall

A Maximum temperature - 1432°C (B2)

Minimum temperature - 1288°C (C1)

A Average temperature - 1347°C

A Burner temperature deviation - 144°C

E Maximum temperature - 1512°C (B2)

E Minimum temperature - 1285°C (C1)

E Average temperature - 1364°C

E Burner temperature deviation - 227°C

Flame stability analysis of a front wall burner

Unstable burners - B1, B3, B4, B5, C1, C3, C4, C5

Flame stability analysis of a rear wall burner

Unstable burners - A1, A2, A3, A4, A5, E1, E2, E3, E4

Summarize / Summarize

Test Results:

Layer B has a temperature deviation of 225 °C; The temperature deviation of the E layer is 227 °C; 80% of the burners on the front wall burn unsteadily; 90% of the burners on the back wall burn unsteadily. According to the test data, it reflects that there is a great potential for combustion improvement in the boiler of Unit #1 of the Song Hau Power Plant in Vietnam.

Safefire has been focusing on the field of safe combustion for many years, providing protection for the safe and stable operation of boilers, and also paying great attention to energy conservation and emission reduction. In the future, we will continue to devote ourselves to a cleaner combustion and coexist with the mountains and rivers!