Application Scenarios

Make combustion cleaner, more efficient and safer

In three months, the combustion efficiency of the boiler increased by 1.44%

In October 2024, the PLTU Pelabuhan Ratu2 power plant under the Indonesian State Power Group deepened its cooperation with Safefire again by installing a layer of TempVision 5000 online temperature field measurement system.

In January 2025, after using the TempVision 5000 for three months, the boiler combustion efficiency increased from 81.29% to 82.73%, and the efficiency increased by 1.44%, achieving a comprehensive understanding of the boiler combustion status and a significant improvement in efficiency.

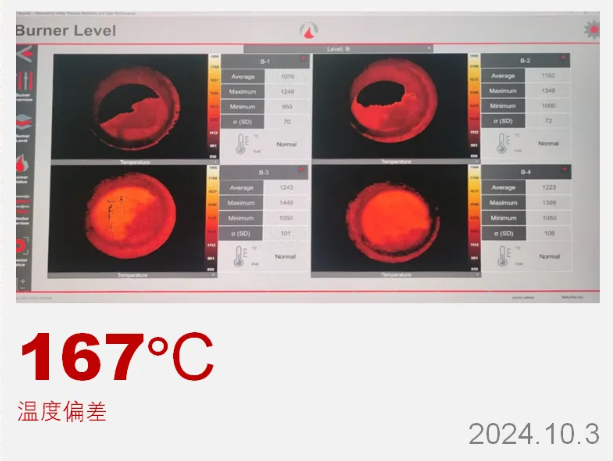

Through the adjustment, the temperature deviation of the four burners on the same floor was reduced from 167°C to 27°C, which effectively improved the adequacy and stability of combustion in the furnace, and reduced the risk of pipe burst and NOx exceedance caused by partial burning and local overtemperature.

Run a summary

After three months of operation, it has been verified that the TempVision 5000 system can truly realize transparent combustion of boilers, help users grasp the combustion status of the boiler around the clock, and guide the daily combustion adjustment work through massive real-time temperature data output, and finally achieve energy conservation and emission reduction.